Our Specialty Defines Excellence

Mould Machining – Core and Cavity

At Laser Cutting Edge, we specialize in machining both core and cavity blocks with tight tolerances using advanced VMCs, CNC milling, and EDM technology. We work with a variety of tool steels, hardened materials, and high-performance alloys to ensure durability and accuracy. Our expertise lies in producing complex geometries, fine details, and smooth finishes that enhance mold performance and product consistency.

Contact Us

Dies and Punch

Our team uses advanced CNC and VMC machining, combined with hardened tool steels, to craft dies and punches that can withstand high pressure and repetitive operations without deformation or wear. Each component is custom-engineered to meet the specific requirements of your application, ensuring perfect clearance, sharp edges, and tight tolerances.

Contact Us

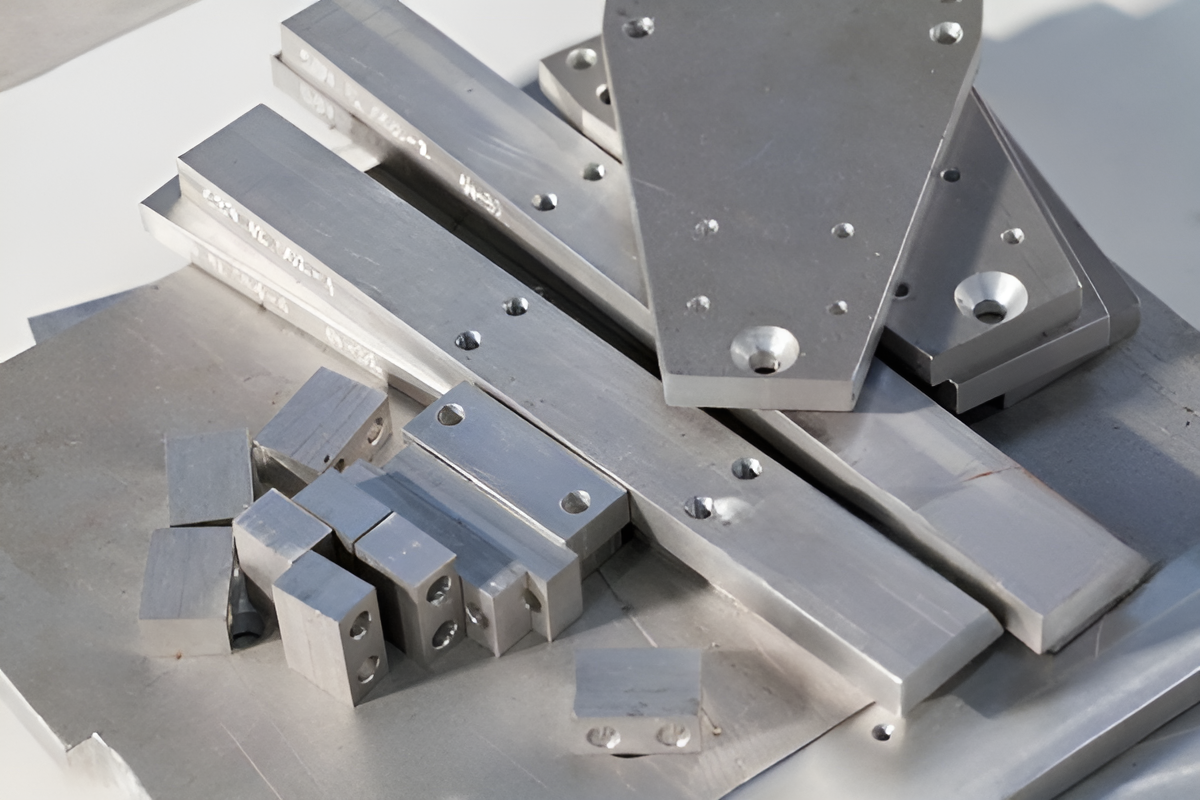

Aluminum Dummies

Aluminum Dummies are essential prototypes or trial components used in mold testing, assembly validation, or production simulations before final manufacturing. At Laser Cutting Edge, we specialize in designing and machining high-precision aluminum dummies that replicate the exact dimensions and geometry of the final part.

Contact Us

MS Casting

MS Casting (Mild Steel Casting) is a robust and cost-effective solution for producing durable components with excellent mechanical properties. At Laser Cutting Edge, we offer high-quality MS casting services for a wide range of industrial applications including automotive, construction, machinery, and infrastructure.

Contact Us

All Types of Tool Room Work

At Laser Cutting Edge, we offer comprehensive Tool Room Work services to support industries with precision tooling and component manufacturing. Our state-of-the-art facility is equipped with VMCs, CNC machines, EDM, surface grinders, and precision measuring instruments, enabling us to handle a wide range of tool room operations with high accuracy.

Contact Us