CNC 5-Axis Bending Services – Laser Cutting Edge

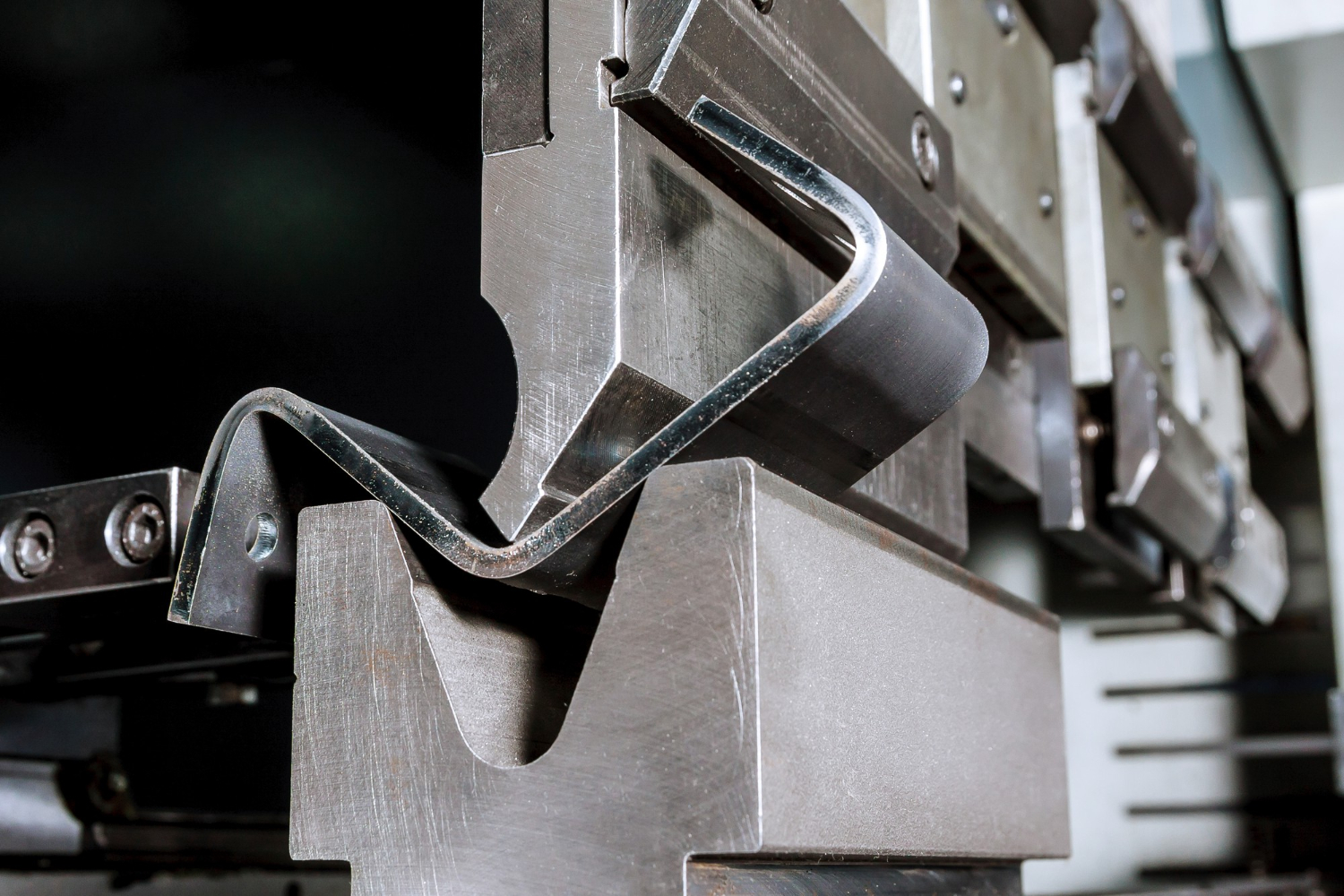

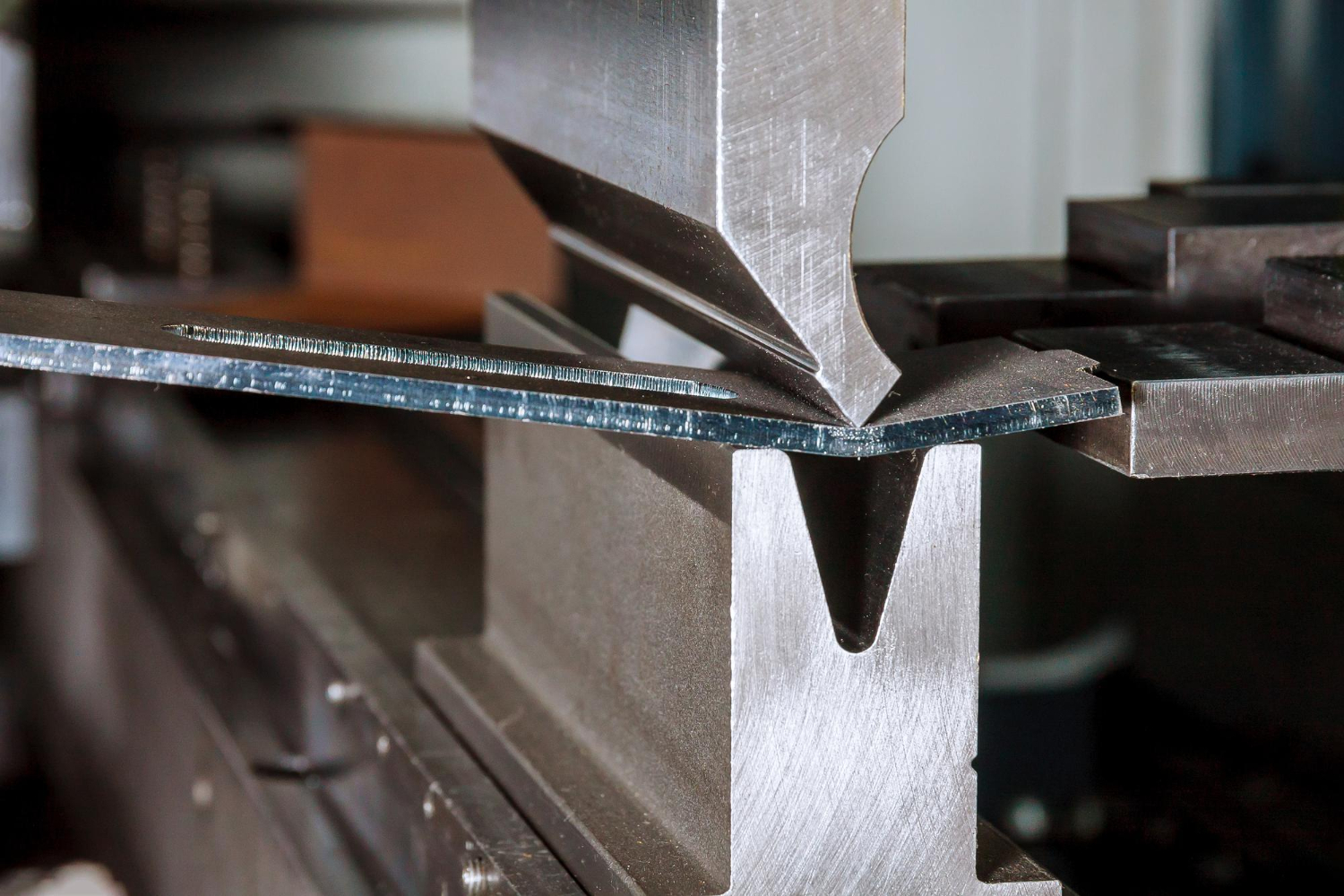

At Laser Cutting Edge, we offer advanced CNC 5-axis bending services that deliver unmatched precision, flexibility, and complexity in metal forming. Our state-of-the-art bending machines are capable of bending parts at multiple angles and orientations in a single setup, reducing production time and increasing consistency.

With 5-axis control, we can handle complex geometries, tight radii, and high-strength materials, making it ideal for industries like automotive, aerospace, architecture, and custom fabrication. Our team ensures that each component is manufactured to exact specifications, with a strong focus on accuracy and repeatability.

Whether it's prototyping or large-volume production, Laser Cutting Edge provides innovative bending solutions tailored to your project needs.

key features of laser cutting

- Allows precise bending of intricate and multi-angle parts in a single setup.

- Achieves tight tolerances and repeatability with servo-controlled axes.

- Minimizes repositioning and manual intervention, boosting productivity.

- Handles a wide range of sheet materials, including stainless steel, aluminum, and alloys.

- Enables direct programming from 3D models for faster prototyping and production.

- Ensures uniform bends across batches, ideal for large-volume production.

- Suitable for complex enclosures, brackets, architectural panels, and custom components.

Why Choose CNC 5-Axis Bending ?

At Laser Cutting Edge, we harness the precision and versatility of CNC 5-axis bending to deliver high-performance, complex metal bending solutions. Unlike traditional methods, 5-axis bending allows for multi-directional bending in a single setup, reducing manual intervention, part repositioning, and errors. This advanced technology ensures tight tolerances, faster turnaround times, and consistent quality—making it ideal for intricate parts and custom applications. Whether you're in automotive, aerospace, or architectural fabrication, our 5-axis bending capabilities guarantee efficiency, accuracy, and design freedom.